how to improve accuracy of rockwell hardness test|rockwell hardness test scale : distributing TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 . WEBVideo Results For: andressa urach elisa sanches. 22 videos. Most Relevant. Filters. Ads By Traffic Junky. 1080p 11:00. Elisa Sanches is back and her new girlfriend Danny .

{plog:ftitle_list}

Catarina Paolino. 𝑺𝒆 𝒗𝒐𝒄𝒆̂ 𝒋𝒂́ 𝒕𝒊𝒗𝒆𝒓 𝒕𝒊𝒓𝒂𝒅𝒐 𝒂 𝒄𝒆𝒏𝒔𝒖𝒓𝒂 𝒅𝒐 𝒕𝒆𝒍𝒆𝒈𝒓𝒂𝒎 𝒑𝒐𝒅𝒆 𝒊𝒈𝒏𝒐𝒓𝒂𝒓 𝒐 𝒑𝒓𝒐𝒄𝒆𝒅𝒊𝒎𝒆𝒏𝒕𝒐 𝒅𝒐 𝒈𝒓𝒖𝒑𝒐 𝒂𝒄𝒊𝒎𝒂 𝒆 𝒊𝒓 .

reducing Rockwell hardness testing errors and guarantees the accuracy and reliability of heat treatment tests and hardness inspection of products. The result of the trial application.

reducing Rockwell hardness testing errors and guarantees the accuracy and .© 2008-2024 ResearchGate GmbH. All rights reserved. Terms; Privacy; IP .TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .A data evaluation method has been established for calculating the indenter’s area function from its measured 3D geometry. The correction method of hardness values based on the indenter’s .

Paramount to accurate and reliable Rockwell hardness results is ensuring that the operators and the methods used are following proper test technique and practice. The precise nature and exactness of a Rockwell test . The purpose of this Guide is to explain the causes of variability in Rockwell hardness test results and to supplenment the information given in test method standards with .

types of rockwell hardness test

The Rockwell hardness test continues to be applied as a tool for assessing the properties of a product while the tolerances on the acceptable material hardness have become tighter and .The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied .The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice.

If you are interested in obtaining a complete understanding and holistic background of the Rockwell hardness test, we recommend diving deeper into the ASTM E18-20 Standard Test Methods for Rockwell Hardness . In order to reduce the testing errors in Rockwell hardness of metal specimens and improve the accuracy of hardness testing, several methods had been tried out and examined based on GB/T 230 and other relevant inspection specifications, firstly, correct the hardness of testing pieces directly by using the hardness reference blocks to calibrate the hardness .Hardness Methods: The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y The Rockwell Hardness Test is actually one of several tests aimed to gauge a material’s compatibility as a component to an object based on their strength and durability. . there is no need for the sample to undergo .

V. Factors for the Accuracy of the Rockwell Hardness Test. While the Rockwell hardness test has its uniqueness, its accuracy is also guided by some critical factors you need to consider before engaging in this test method. Rockwell Testing Machine – The machine itself is one critical consideration for an accurate Rockwell test result. And .

A Struers universal hardness tester can test with Rockwell, Vickers, Brinell, and Knoop. That gives you flexibility in material testing. READ MORE. DuraVersa 100. . Improve the accuracy and efficiency of your sample preparation with Struers equipment courses - learn from the experts in metallographic sample preparation. .Improve the accuracy and efficiency of your sample preparation with Struers equipment courses - learn from the experts in metallographic sample preparation. . The Rockwell hardness test is used for macro hardness tests, which are generally defined as tests that use indentation loads below or equal to 1 kgf. Therefore, a ground surface is .How Technicians Perform the Rockwell Hardness Test. . Since 1906, we’ve been manufacturing durable, accurate blades at affordable prices. Since then, our precision knife and saw blades have served thousands of American businesses to stay sharp and prosperous. For more information on Rockwell hardness testing and how you can benefit from .The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article.

Improve the accuracy and efficiency of your sample preparation with Struers equipment courses - learn from the experts in metallographic sample preparation. . The Rockwell hardness test. Rockwell is a fast hardness test method developed for production control, with a direct readout, mainly used for metallic materials. . During a Rockwell hardness test, an accurately shaped indenter makes an indent into the test sample to determine the sample's hardness value. . necessitates a basic knowledge of the factors that must be considered in choosing the correct scale to ensure an accurate Rockwell test. The choice is not only between the regular hardness test and .

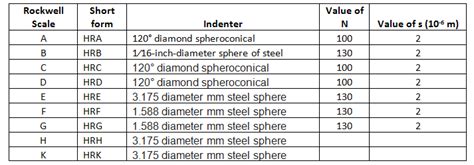

Rockwell Hardness Test formula. Your testing equipment will provide an accurate calculation of the Rockwell hardness result, but there’s a formula to calculate the depth that’s measured into a Rockwell hardness number, which is: HR=N-(d/s) Where the value of: d is the penetration depth measured from point zero in mm s is either 0.001 mm or . A recorded hardness number of 63HRC signifies a hardness of 63 on the Rockwell C scale. Higher values indicate harder materials such as hardened steel or tungsten carbide. These can have HRC values in excess of 70HRC. Rockwell test forces can be applied by either closed-loop load cell or traditional deadweight systems. Brinell Hardness Test (ASTM E10) Rockwell (ASTM E18) Vickers; Knoop ; Brinell v Rockwell Hardness Test Hardness Test Characteristics General characteristics of hardness-testing methods and formulas for calculating hardness. Hardness Scale. The chart below is used for converting various hardness scales. Since all the hardness test are limited in . Failure to properly prepare and execute a Rockwell hardness test can result in compromised test data or false readings, potentially contributing to the production and delivery of substandard product. . a basic knowledge of the factors that must be considered in choosing the correct scale to ensure an accurate Rockwell test in necessary. The .

Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, .

Improve the accuracy and efficiency of your sample preparation with Struers equipment courses - learn from the experts in metallographic sample preparation. . Find out more about the Rockwell hardness test. Jominy testing . The Rockwell hardness test involves applying a sequence of loads to the material and measuring the depth of the resulting indentation, which indicates the material’s hardness. . Ensuring Accurate and Reliable Hardness Testing Results. To ensure accurate and reliable hardness values during testing, consider the following general tips: .

The Rockwell Hardness Test is the most accurate method of measuring the hardness of a material, and it is easier to perform than the Brinell or Vickers tests.01. II. Theory and Principle of the Rockwell Hardness Test. The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the .Many Rockwell test standards also stated that while processing the test, there should be a distance of more than 2.5 times the diameter of the indentation between mid of an indentation and the periphery of the material. Thickness of Test Material In the Rockwell hardness test, indentation depth depends on the thickness of the material.

Rockwell hardness test for plastics: In this test, a load of 15 or 30 kg is applied to the surface of the plastic material for a few seconds. . Reliable and accurate results: The Brinell hardness test is known for its reliability and accuracy in measuring the hardness of materials. It is widely used in various industries for this reason.

There are myriads of hardness tests out there, however the Rockwell hardness test is the most common hardness test used in the metalworking industry today, due to its speed and accuracy. The test must be carried out with a specific type of scale or tester, called a Rockwell hardness scale. How It Works. The hardness test is done through a .

A Struers universal hardness tester can test with Rockwell, Vickers, Brinell, and Knoop. That gives you flexibility in material testing. READ MORE. DuraVersa 100. . Improve the accuracy and efficiency of your sample preparation with Struers equipment courses - learn from the experts in metallographic sample preparation. .Figure 23.4 Schematic of the Rockwell indentation process using a diamond brale Indenter. The Rockwell hardness test is based on the measurement of the depth to which an indenter is forced by a heavy (major) load beyond the depth resulting from a previously applied preliminary (minor) load. The test follows the sequence, see Figure 23.4 to your . In the Rockwell hardness test, prior to applying the testing load, a small minor load is applied to seat the indenter into the test piece and remove the effect of any surface irregularities. . Given that the references used for the Mohs scale do not have a graded increase, the Mohs scale lacks accuracy and is only a rough measure of hardness . This method is well-suited for coarse or heterogeneous materials due to its large indentation area and high measurement accuracy. However, due to the large indentation size, inspection of finished products can be challenging. . Fig. 3-17 Schematic Diagram of the Principle and Test Process of Rockwell Hardness Test (a) Add preload (b) Add main .

The Rockwell hardness test is an essential tool in material science, offering a fast and trustworthy way to measure how hard materials are, with a special focus on metals. This technique gauges how deeply an indenter presses into a material under a heavy load compared to its penetration under a lighter one. It is universally [.] The Rockwell indentation hardness test, developed by Hugh and Stanley Rockwell in 1919, is perhaps the most recognized and widely used. This method is characterized as a differential depth method. It uses the depth of the indentation as a measurement of hardness. . reduce operator influence and increase accuracy and repeatability. Source .

rockwell hardness test scale

23 de out. de 2023 · O conflito entre Graciele Lacerda e Amabylle Eiroa segue repercutindo nas redes sociais. Tudo começou quando a nora de Zezé Di Camargo fez uma carta aberta aos seus seguidores, revelando que descobriu que uma pessoa de seu convívio criou um perfil falso para difamá-la na internet e entre os parentes. Após o desabafo, internautas .

how to improve accuracy of rockwell hardness test|rockwell hardness test scale